Stereolithography is an additive manufacturing technology that builds three-dimensional parts layer-by-layer using a laser to cure liquid resin.

What is Stereolithography (SLA)?

Stereolithography is an additive manufacturing technology (3D printing process) that falls under the VAT photopolymerisation category. Vat photopolymerisation is one of the seven types of additive manufacturing technologies.

SLA stands for Stereolithography, an additive manufacturing technology that builds three-dimensional models layer-by-layer using a laser to cure liquid resin.

SLA involves laser curing of a liquid photopolymer resin into the desired shape. This process is possible because the photopolymer, as the name suggests, contains a compound called photoinitiators that reacts when the laser light is applied.

Since the laser light is a focused UV beam, it is possible to cure a specific portion of the liquid photopolymer. This feature makes it possible to generate a layer of the cross-section of the desired model on the X-Y plane. Therefore, repeating the process along the Z-axis results in a solid 3D model.

| Materials | Photopolymer resins – thermosets |

| Support | Always required ( Part design depended) |

| Common layer thickness | 0.025 – 0.1 mm (0.001″ – 0.004″) |

| Dimensional accuracy – Desktop | ± 0.5% (lower limit: ±0.10 mm (±0.004″) |

| Dimensional accuracy – Industrial | ± 0.15% (lower limit ± 0.01 mm (±0.0004″) |

| Typical build volume – Desktop | Up to 145 x 145 x 175mm (5.8″ x 5.8″ x 7″) |

| Typical build volume – Industrial | Up to 1500 x 750 x 500mm (60″ x 30″ x 20″) |

How does Stereolithography (SLA) work?

SLA printer overview

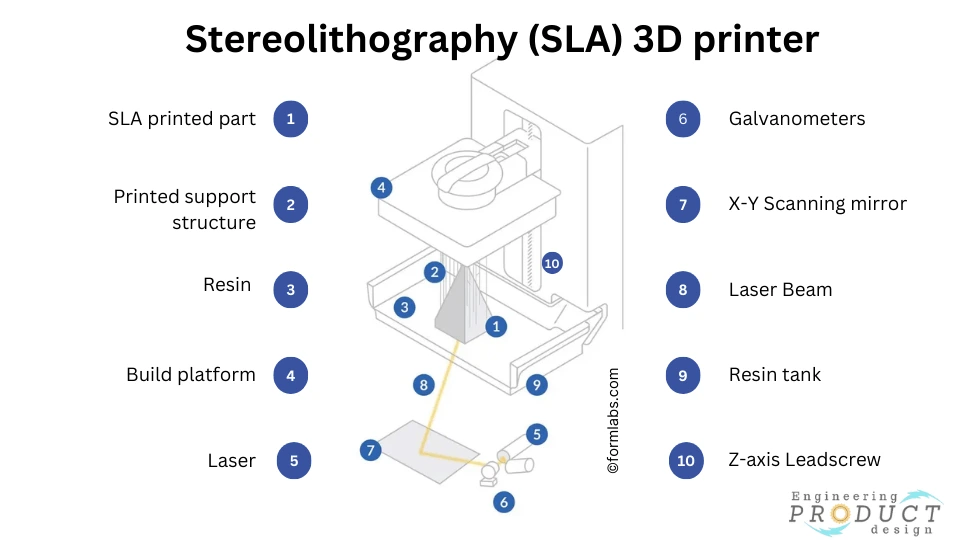

A traditional SLA printer consists of the following:

- A resin tank containing the liquid photopolymer

- A build platform connected to the moving Z-axis typically uses a lead screw. This platform holds the printed part as it goes through the SLA process. The Z-axis layer height dictates the verticle print resolution.

- A laser shines the beam via mirrors to move the laser beam along the X-Y plane.

While this is the traditional configuration, it is essential to highlight that some printers use the upside-down or inverted SLA process. The figure above shows an upside-down type of printer configuration.

Stereolithography (SLA) process steps

Creating a 3D model through SLA takes the following steps:

- The resin tank is filled with the photopolymer.

- The building platform is positioned at the highest possible point, ensuring a thin photopolymer layer covers it.

- Using the instructions provided by the software, the printer focuses the laser beam upon the corresponding surface area while moving across the X-Y plane to generate the desired layer.

- The laser cures the photopolymer until the layer is solid, thus forming the cross-section of the model.

- The building platform moves down so a new layer of liquid photopolymer covers the cured layer.

- The printer repeats steps 3-5 until the model is complete.

- The resulting part is removed from the printer, dried, and cleaned using ultrasound and alcohol. At this point, the operator must remove any support structures.

Advantages and disadvantages of Stereolithography

What are the advantages of Stereolithography?

- Reusable material – It is possible to use the portion of liquid photopolymer (not cured) that remains in the tank for further printing. This characteristic reduces material consumption.

- Tight tolerances – SLA can achieve tolerances as low as 0.01mm (0.0004″)

- Complex geometries – SLA can generate models with complex geometries, including oblique surfaces, without compromising the print quality.

- Smooth finish – SLA prints come out with smooth surface finishes directly from the printer. This feature reduces the need for further surface treatments.

- Large parts – Industrial SLA printers make it possible to 3D print components with sizes up to 1500 x 750 x 500mm (60″ x 30″ x 20″).

What are the disadvantages of Stereolithography?

- Non-functional prototypes – SLA prints are usually fragile, so they are not as adequate as functional prototypes.

- Photosensitivity – Given the nature of the process, SLA prints are sensitive to sunlight. It means the mechanical and visual properties can degrade if exposed to the sun.

- Required support structures – SLA requires support structures for all prints, no matter their geometry. This requirement impacts the amount of material needed. It also increases production times since postprocessing to remove these structures is necessary.

- Initial costs – The initial investment required to produce SLA prototypes may be high. At the industrial level, SLA machines can range between 100,000 and 400,000 US dollars, depending on their capacity. Regarding materials, the range is between 50 and 400 US dollars per litre, depending on the properties needed.

Stereolithography materials

What materials can be used for SLA printing?

There are different types of liquid photopolymer resins, known as light-reactive thermoset materials, for SLA. Each option provides specific properties. The most common materials used in SLA include:

- Standard resin – Standard resin is the cheapest and offers a smooth surface finish. However, the print is usually fragile. Standard resin is a top option for rapid prototyping.

- Clear resin – As the name suggests, this resin results in translucid parts, but postprocessing is required to achieve this feature. Mechanical properties are similar to the standard resin, and it is also great for rapid prototyping, especially in fluid or lighting applications, given the translucid characteristic.

- High-detail resin – This material is similar to the standard resin. The main difference in this one is that it offers a higher degree of accuracy (lower tolerances) but comes at a higher price.

- Tough and durable resin – As the name implies, this material offers higher toughness and durability. Mechanical properties are similar to other strong materials like ABS or PP. According to 3DS, some SLA prints made with these materials have a tensile strength of 55.7 MPa and a modulus of elasticity of 2.7 GPa. Such properties make these materials engineering-level resins.

- Castable resin – The main properties of castable resins are that they work well with highly complex geometries. They also offer very smooth surface finishes. Moreover, these resins leave almost no residue after burnout. As a result, these are considered the best option for mould patterns and products like jewellery.

- High-temperature resin – Also known as heat-resistant resins, these materials can withstand very high temperatures with a heat deflection of up to 300°C (572°F). Therefore, these resins are the option when fabricating parts exposed to high temperatures, such as casting and thermoforming tooling.

- Flexible resin – The resulting part made with this type of resin is similar to one made with rubber, thus offering high elongation at break and a low tensile modulus. This feature makes it great for applications where compression or bending is required. However, dimensional accuracy is a limitation of this material.

- Dental and medical resin – This type of resin has similar properties to others but with a significant difference in biocompatibility.

SLA vs SLS

Stereolithography (SLA) and Selective Laser Sintering (SLS) are additive manufacturing technologies that utilise lasers to build 3D objects layer-by-layer.

However, they have some differences that are worth highlighting.

- Materials used – While SLA uses UV light to solidify a liquid resin in specific areas to form the desired 3D shape, SLS involves selectively melting a layer of powdered material with the laser to create a solid object.

- Build speed – SLS is a quicker process than SLA. This capability is a significant advantage of SLS over SLA since it can print more parts over the same period. It also makes SLS a better option for rapid prototyping.

- Precision – SLA offers the possibility of achieving tighter tolerances than SLS.

- Support structures – While SLA always requires support structures to build the model, SLS does not require any support structures since the powder surrounding the build supports any overhanging geometry.

- Mechanical properties – As mentioned above, SLA parts are usually fragile and do not serve as functional parts. On the contrary, SLS parts offer improved mechanical properties that make them tough enough to work as functional prototypes.

Recommended references

- Jacobs, P. F. (2012). Stereolithography and Other RP&M Technologies: From Rapid Prototyping to Rapid Tooling. Society of Manufacturing Engineers.

- Kochan, D. (2007). Stereolithography: Materials, Processes and Applications. Springer Science+Business Media.

- Fidan, I., Loh, H. T., & Jahan, A. (2012). Stereolithography: Materials, Processes, and Applications. McGraw-Hill Education.

No comments:

Post a Comment