What is Biomass ?

- The meaning of Biomass is an organic material which derived from living organisms likes plants and animals.

- The most common biomass materials used for energy are plants, wood, and waste.

- These are called biomass feedstocks. Biomass energy can also be a nonrenewable energy source.

- Some biomass waste cane be used to generate electricity as it is presented in the post of biomass energy.

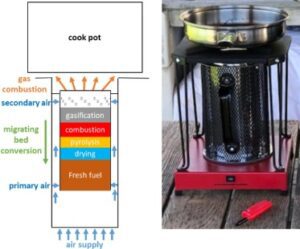

- The availability, combustion efficiency, and cost decide the selection of biomass for domestic cooking.

Types of Biomass Used for Cooking

- The best biomass for cooking can vary depending on your specific needs and location.

- Biomass refers to organic materials used as fuel for cooking, and different types of biomass may be more suitable in different situations.

- Here are some common biomass sources for cooking:

Wood:

- Wood is one of the most widely used biomass fuels for cooking worldwide.

- It’s readily available in many regions and can provide a consistent source of heat.

- However, it’s important to use sustainable harvesting practices to prevent deforestation.

Crop Residues

- Agricultural crop residues such as rice straw, corn cobs

- wheat husks can be used as biomass for cooking in regions where these crops are prevalent.

- They are often readily available after harvest.

- The heating value of crop residues like rice straw, corn cobs, and wheat straw is generally lower than that of wood.

- They typically have heating values in the range of 13-17 million BTU per ton, depending on moisture content and type.

- The heating value of agricultural waste pellets can vary significantly depending on the type of agricultural waste used, its moisture content, and the specific pelletization process employed.

- Generally, agricultural waste pellets have a heating value ranging from 14 to 18 megajoules per kilogram (MJ/kg) or approximately 3,500 to 4,500 kilocalories per kilogram (kcal/kg)

Animal Dung:

- In some areas, dried animal dung, like cow dung or buffalo dung, is used as a biomass fuel for cooking.

- It’s abundant in rural settings and can be an efficient fuel when properly dried and prepared.

Charcoal

- Charcoal is a derivative of wood or other organic materials that have been heated in the absence of oxygen.

- It burns cleanly and can provide a consistent source of heat.

- However, the production of charcoal can be environmentally damaging if not done sustainably.

Biogas:

- Biogas is produced from the anaerobic digestion of organic materials such as manure, food waste, or agricultural residues.

- It can be used for cooking when it’s readily available and properly processed.

Pellets

- Biomass pellets are made from compressed organic materials, typically wood or agricultural residues.

- They are convenient to store and use and can be a good option for cooking.

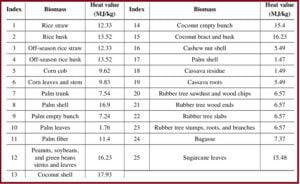

Heating Values of Biomass Materials

- The heating value of biomass materials, also known as the calorific value or energy content

- It is a measure of the energy that can be released when the biomass is burned.

- It’s typically measured in units like megajoules per kilogram (MJ/kg) or kilocalories per kilogram (kcal/kg).

- The firing rate of biomass and efficiency of stove can be calculated using the mass and heating value as formals given in the post. Compare the heating value of biomass per unit mass of fuel burning and determine the its cost relative to LPG gas which is expensive in Asian and African counties.

- Here’s a rough comparison of the heating values of different biomass materials:

Wood

- The heating value of wood varies depending on the type of wood (e.g., hardwood or softwood) and its moisture content.

- Dry hardwoods can have a heating value of around 20-24 million British thermal units (BTU) per cord,

- while softwoods typically have slightly lower values.

- The heating value of wood pellets, a common processed wood biomass, is around 8,000-9,000 BTU per pound

- Heating value of wood in SI Units

- Hardwood: 18-21 MJ/kg

- Softwood: 15-18 MJ/kg

- Wood pellets: 17-19 MJ/kg

Biomass Bamboo

- The heating value of biomass bamboo pellets can vary depending on factors such as the moisture content of the pellets and the specific type of bamboo used.

- However, as a general guideline, the heating value of bamboo pellets typically falls within the range of 16 to 19 megajoules per kilogram (MJ/kg),

- which is roughly equivalent to 4,000 to 4,500 kilocalories per kilogram (kcal/kg).

- Bamboo is considered a suitable source of biomass for pellet production due to its fast growth rate, high cellulose content, and low ash content.

- These characteristics make it a valuable renewable energy resource for heating and power generation.

- It’s worth noting that the heating value of bamboo pellets can be affected by factors such as the pelletization process, the age of the bamboo, and the specific species of bamboo used.

- To obtain precise information on the heating value of a particular batch of bamboo pellets, it’s advisable to check with the manufacturer or conduct laboratory testing if necessary.

Crop Residues

- The heating value of dried animal dung, such as cow dung, can vary widely depending on factors like animal diet and drying methods.

- It generally falls in the range of 5-10 million BTU per ton.

- Heating value of crop residues in SI Units

- Rice straw: 12-14 MJ/kg

- Corn cobs: 15-17 MJ/kg

- Wheat straw: 13-15 MJ/kg

Animal Dung

- The heating value of dried animal dung, such as cow dung, can vary widely depending on factors like animal diet and drying methods.

- It generally falls in the range of 5-10 million BTU per ton.

- Cow dung: 7-10 MJ/kg (dried)

Charcoal

- Charcoal has a higher heating value compared to raw wood because it’s essentially pure carbon.

- It can have a heating value of around 25-30 million BTU per ton.

- It can have a heating value of around 25-30 million BTU per ton

- The heating value of crop residues in SI Units for Charcoal from wood is 25-30 MJ/kg

Biogas

- Biogas produced from organic materials through anaerobic digestion contains methane

- It has a heating value of about 1,000-1,100 BTU per cubic meter.

- The heating value can vary depending on the methane content of the biogas.

- Methane content in biogas: 55-70% (calorific value varies based on methane content)

Wood Pellets

- Biomass pellets, which are often made from compressed wood or agricultural residues, have a heating value of roughly 7,000-9,000 BTU per pound.

- This value can vary depending on the type of biomass used and the pellet production process

- Wood pellets: 17-19 MJ/kg

- Crop residue pellets: Calorific value can vary based on the type of crop residue.

- The comparison of biomass pellets and briquettes for cooking is given in the post on this website.

- Compare the heating value and cost of stoves while determining the budget and applications of stoves.

Biomass Briquette

- The heating value of biomass briquettes can vary based on the type of biomass used, the production process, and the moisture content of the briquettes.

- Biomass briquettes are compressed blocks of biomass materials, typically made from agricultural residues, wood waste, or other organic matter.

- They are designed to have higher energy density and better combustion characteristics compared to the original biomass materials.

- On average, biomass briquettes can have a heating value ranging from about 4,000 to 5,000 kilocalories per kilogram (kcal/kg) or around 14,000 to 18,000 British thermal units per pound (BTU/lb).

- This heating value is similar to or slightly lower than that of wood pellets, which are another common type of processed biomass fuel

- It’s important to note that these values can vary depending on factors such as moisture content, density, and the specific type and quality of the biomass.

- Additionally, the heating value is not the only factor to consider when choosing a biomass material for energy purposes.

- Other factors include availability, ease of handling, storage, combustion efficiency, and environmental impact.

- The “best” biomass for your stove will depend on your specific circumstances.

- If you have access to a variety of biomass materials, you may want to consider factors like cost, availability, energy content, and emissions when making your choice.

- Additionally, using an efficient stove designed for the type of biomass you plan to use can significantly improve cooking performance while reducing environmental impact.

- In regions with concerns about indoor air pollution, cleaner-burning fuels like liquefied petroleum gas (LPG) or electricity may be preferred for stoves. These fuels produce fewer emissions and are easier on indoor air quality.

Effect of Climate on Biomass Heating Value

Climate can have an indirect effect on the heating value of biomass by influencing the growth conditions and composition of the biomass feedstock. The primary factors related to climate that can affect the heating value of biomass include temperature, precipitation, and growing season length:

Temperature:

- Temperature plays a crucial role in determining the growth rate and the chemical composition of plants used as biomass feedstock.

- In regions with warmer temperatures, biomass crops like switchgrass or miscanthus may grow more quickly and produce biomass with a potentially higher heating value due to increased cellulose and lignin content.

- However, extreme heat can also stress plants, potentially reducing their biomass quality.

Precipitation:

- Adequate moisture levels are essential for plant growth and biomass production.

- In regions with sufficient rainfall or irrigation, biomass crops can thrive and produce higher yields.

- Proper moisture levels can also contribute to the formation of biomass with better heating value. Conversely, drought conditions can lead to reduced biomass growth and lower heating values.

Growing Season Length:

- The length of the growing season is influenced by temperature and determines how long plants have to accumulate biomass.

- Longer growing seasons in warmer climates can allow for more biomass accumulation, potentially resulting in higher heating values.

Species Selection:

- Climate can also influence the choice of biomass species.

- Different plant species have varying heating values, growth requirements, and adaptability to specific climate conditions.

- Some species may perform better in cooler or wetter climates, while others thrive in warmer or drier regions.

Harvest Timing:

- The timing of biomass harvest can be influenced by climate conditions. Harvesting at the right time can maximize biomass yield and quality, as well as heating value.

Storage and Drying:

- Climate conditions can impact the storage and drying of biomass. In regions with high humidity, biomass may require more extensive drying efforts to reduce moisture content and improve its combustion properties.

- It’s essential to note that while climate can influence the quality and yield of biomass feedstock, other factors such as soil quality, fertilization, and crop management practices also play significant roles. Biomass quality can vary widely based on these combined factors.

- Finally, to maximize the heating value of biomass, it’s essential to choose appropriate feedstock species for the local climate, employ proper cultivation and harvesting techniques, and ensure proper storage and moisture control measures are in place

Conclusion

- The choice of the best biomass for cooking depends on factors such as local availability, sustainability, efficiency, and the type of cooking equipment being used.

- In many cases, a combination of biomass sources may be used to meet different cooking needs.

- It’s also important to consider the environmental impact and health effects of biomass cooking, as some types of biomass fuel can produce indoor air pollution and contribute to deforestation if not managed sustainably.

- When evaluating the best biomass material for a specific application, it’s recommended to conduct detailed tests or consult with experts to determine the most accurate and appropriate heating values for your situation.

Reference

- Ontario, Biomass Burn Characteristcis, 2011

- Pen state, Characteristic of Biomass Fuel, 2010