Material Jetting is one of the seven types of Additive manufacturing technologies in which droplets of material are selectively jetted and cured to form part.

What is Material Jetting?

Material Jetting (MJ) is one of the 7 types of Additive Manufacturing (AM) technologies in which droplets of build and support materials are selectively jetted onto the build platform and cured by either ultraviolet light or heat to form a 3D object. The material can be jetted continuously or only when required, i.e. on-demand to create the parts.

The material jetting technique is very similar to standard inkjet printers, where the material droplets are selectively deposited by jetting layer by layer to create a three-dimensional object. Once a layer is complete, it’s cured by either ultraviolet light in the case of photosensitive material or heat cured for metal and ceramic parts.

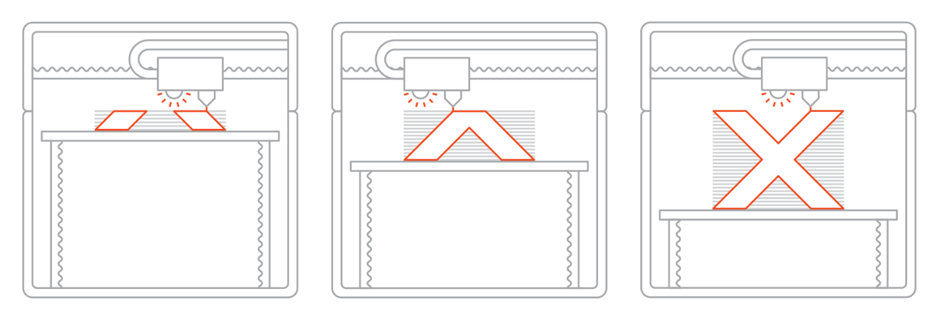

Like most of the additive manufacturing technology machines working principles, the deposition of the material is controlled by X, Y and Z movement, which slightly varies from manufacturer to manufacturer to create the object in 3d space.

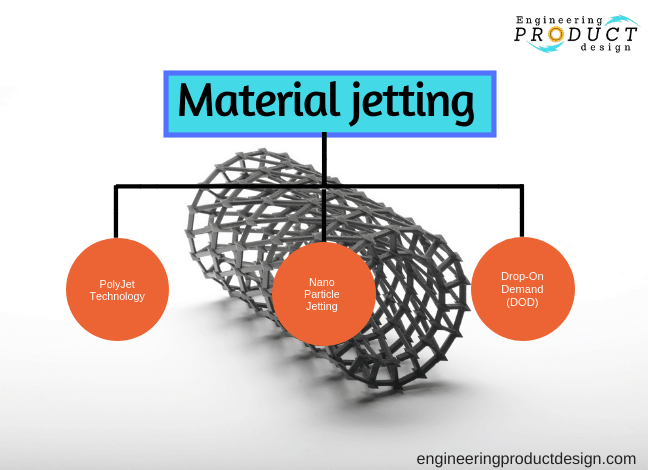

Types of Material Jetting (MJ)

Since the inception of Material jetting technology in the 1990s, several techniques have emerged and progressed into a developed state. Although they differ from manufacturer to manufacturer on how the material is cured and how they are deposited, the underpinning material jetting technique is the same.

They all can be categorised under the following three main types.

- PolyJet technology

- NanoParticle Jetting (NPJ)

- Drop-On Demand (DOD)

PolyJet – Material Jetting

Stratasys PolyJet technology jets ultra-thin layers of photopolymer material onto the build tray, similar to a standard inkjet printer. Each layer is immediately cured by a UV light. The gel-like support material is available for complex geometrical parts, easily removed by hand or using an aqua blast or water jetting.

Many pieces of literature refer to material Jetting technology as ‘PolyJet’, mainly because PolyJet is the first-ever material jetting technology printer introduced (First introduced by Object and later bought by Stratasys).

How does PolyJet material jetting technology work?

After the common steps of how additive manufacturing works, in which the 3D CAD model is converted to layer-based information, it’s ready to be printed.

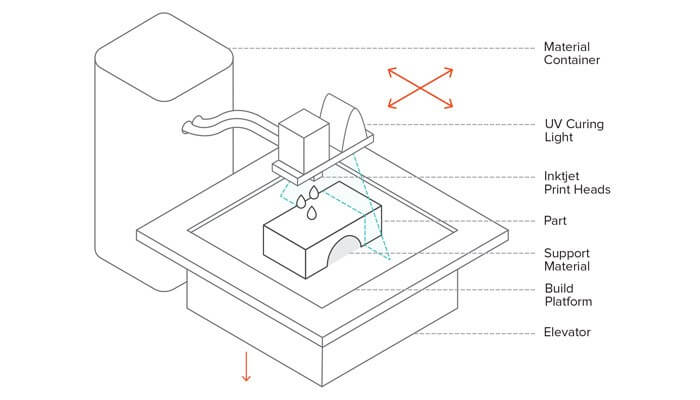

A schematic of a simple Material Jetting or PolyJet process is shown in the figure below to help describe the material jetting method.

- As shown in the above schematic, PolyJet printers have print heads, a build chamber, a material container and UV Curing light.

- The liquid resin inside the container is heated at the start to achieve optimum viscosity suitable for jetting.

- Print head jets thousands of tiny droplets of photopolymer as per the layer information, travelling across the X-Y build platform.

- UV light cures the material deposited and solidifies it to create the layer.

- Once the layer is completed, the build platform is moved downwards to start the next layer

- This process continues until the part has finished printing

Following are some key points about the printing method.

- 14 microns layer resolution and accuracy – smooth-surfaced parts

- Thin walls and complex geometries are possible

- Wider material choices are available

- PolyJet can print rigid and flexible materials in a single build to create over-moulded parts without tooling.

- The multi-material capabilities of material jetting enable the creation of accurate visual and haptic prototypes.

More on PolyJet technology can be found here at https://www.stratasys.com/polyjet-technology.

NanoParticle Jetting (NPJ)

XJet’s NanoParticle jetting technology uses a unique dispersion methodology to deposit the material onto the build platform. Special solid nanoparticles of the build material are contained or suspended in a liquid and then are jetted onto the build tray. Both build and support materials suspended in liquid form are supplied in sealed cartridges. Once the build process is complete, the support material is removed before going through a simple sintering process.

How does the NanoParticle jetting technology work?

- Solid particles in a liquid suspension are loaded using sealed cartridges into the printer.

- Two system printheads with thousands of nozzles simultaneously jet ultrafine drops of both build and support material onto the build tray

- High temperature maintained inside the build area causes the liquid jacket surrounding the nanoparticle to evaporate.

- This leaves dense ultra-fine nanoparticle layers of the build material.

- Produced parts are then sintered, and support material removed

Some key points about the printing method:

- Nanoparticles in ultra-thin layers produce a super fine detailed smooth surface

- High accuracy due to particle size

- Since the build and support particles are in sealed cartridges, reduced risk to health and safety and easy to handle

- Due to the separate material support structure, easy to remove and create complex parts with thin walls, sharp edges, etc.

More on Nanoparticle jetting technology can be found here at https://www.xjet3d.com/technology/.

DOD – Drop on demand

Drop on demand, as the name implies, deposits only tiny dots of material when necessary instead of continuous lines and is typically used for viscous liquid materials. These DOD technology printers use two heads for each build and one support material. Due to their ability to print viscous liquid, these are used exclusively to make wax patterns for investment casting, especially jewellery manufacturing.

This replaces the first few steps of making the master tool in investment casting, cutting the overall cost.

How does Drop-on demand material jetting technology work?

- The printer consists of a build plate, two print heads, cutter head assembly and two cartridges for build and support materials

- Wax material is loaded into the printer as powder. These melt into liquid form inside a heated tank.

- Each layer is printed in a similar way to how generally AM technologies work

- Each layer Is precisely milled to keep the layer thickness and flatness

- Support material is automatically laid down, eliminating the designer’s need to create support structures within the design

- The finished part would be surrounded by support material that goes into a liquid bath

- The support completely dissolves away, leaving behind a clean, high-precision wax model

Some key points about the printing method.

- It can print both resin and wax.

- This technology is specially engineered to produce mould patterns for lost-wax casting or investment casting

- Resolution of +/-22 µm in X & Y and 25 µm for layer thickness

- Layer thickness can be controlled and repeated down to 6µm by the rotating milling blade

- Smooth curvature printing produces the highest precision and surface finish in the industry

- 5000 × 5000 drops per inch dropping resolution produces high-definition parts

Advantages and Disadvantages of Material Jetting

Advantages of Material Jetting

- Highly accurate parts with resolution down to 14 microns

- Due to high accurate layer resolution, it can produce smooth parts with surfaces comparable to injection moulding and very high dimensional accuracy

- Low wastage due to accurate jetting and material on-demand dropping technology, unlike processes like powder bed fusion where sintering takes place inside the power chamber

- Multi-material and multi-colour capability within the same print volume

- Material Jetting has homogeneous mechanical and thermal properties

Disadvantages of Material Jetting

- Material jetted parts are mainly suitable for non-functional prototypes, as they have poor mechanical properties – NPJ and DOD produces better parts than PolyJet in terms of mechanical properties

- Mechanical properties of photosensitive material used in PolyJet, degrade over time quickly.

- Compared to some other AM technologies, MJ machines are still expensive, making it not feasible for some applications.

- Produces relatively brittle parts making it difficult to use in a production load-bearing part

- Although it’s easier to remove, most of the parts often require support material

- High accuracy can be achieved but materials are limited and only polymers and waxes can be used with PolyJet

No comments:

Post a Comment