Directed Energy Deposition forms parts by melting material as it is being deposited using a laser, electron beam or plasma arc.

What is Directed Energy Deposition?

Directed Energy Deposition (DED) is one of the 7 categories of Additive Manufacturing processes. DED forms 3D objects by melting material as it is being deposited using focused thermal energy such as a laser, electron beam or plasma arc. The energy source and the material feed nozzle are manipulated using a gantry system or robotic arm. DED is increasingly used in hybrid manufacturing, where even the substrate bed is moved to create complex shapes.

Although it’s possible to create parts from scratch, due to how the DED technology works; currently, it’s predominately used for repairing by adding material to an existing part, such as turbine blade repair. Directed energy deposition was developed by Sandia National Laboratories in 1995 under the name of LENS (Laser Engineering Net Shape) and then was commercialized by Optomec Design Company. Due to the variations in the energy source and final use, DED is sometimes referred to as laser metal deposition (LMD), 3D laser cladding or direct light fabrication.

Directed energy deposition types

Although DED technology can be used to make metal, ceramic and polymer parts, it is predominately used to make metal parts. DED can be classified into the following groups by the energy source it uses to melt material.

- Laser-based DED systems such as Optomec’s Laser Engineering Net Shape (LENS) DED system uses a laser as the main energy source.

- Electron beam-based DED systems such as Sciaky’s Electron Beam Additive Manufacturing (EBAM) use an electron beam to melt the powdered material feedstock.

- Plasma or Electric arc-based DED systems such as Wire arc additive manufacturing (WAAM) DED process use an electric arc to melt the wire.

Directed energy deposition technology can also be subdivided into the following types based on the material feedstock used to create the parts.

- Powder-based DED systems such as Laser Engineered Net shaping (LENS) or Laser Metal Deposition (LMD) feed powder through the nozzle and melt by a laser beam or electron beam.

- Wire-based DED systems feed wires through a nozzle and use a laser, plasma arc or electron beam to create the molten pool.

How does Directed energy deposition work?

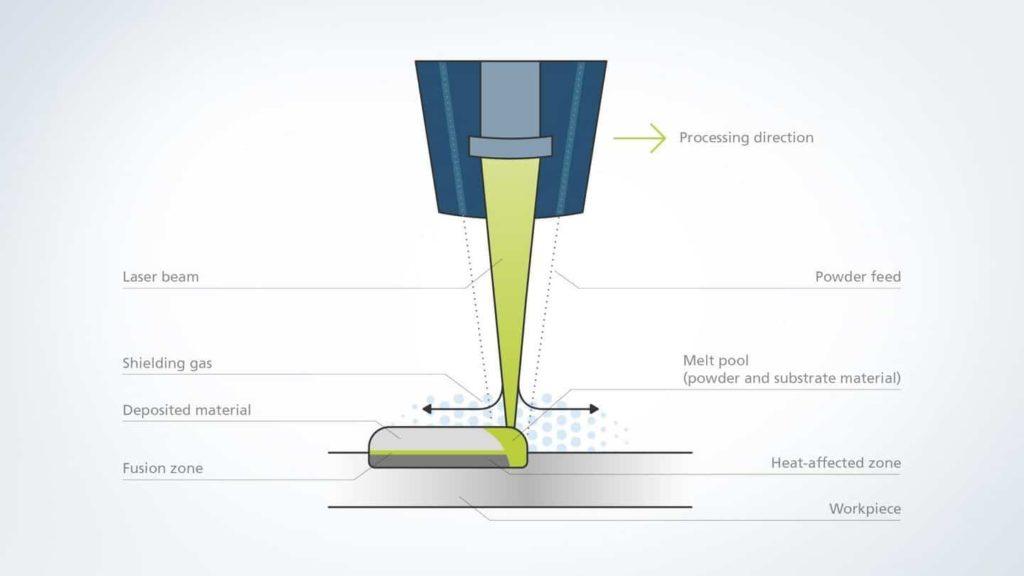

Different types of DED systems discussed in the previous section work marginally differently. However, the powder-based laser DED system can explain the core principle.

Since the process creates a molten metal pool, the DED process typically occurs in a hermetically sealed chamber either filled with inert gas for laser and arc energy source or a vacuum for electron beam systems to stop metal oxidization, especially for reactive materials like Titanium.

The centre of a typical DED system is the nozzle head (figure 2) which consists of the energy source and the powder delivery nozzles, which converges at the point of deposit where the laser beam is focused. The nozzle head is mounted on either a multi-axis CNC (Computer Numerical Control) head or an articulated arm. Typically, the build platform is part of the multi-axis CNC system, which includes the nozzle head.

- The nozzle head and the build platform are moved using the geometric CAD information to generate the 3D geometrical features.

- The laser beam melts the surface and creates a small molten pool of the material on the substrate at the start point along the build path.

- The feeders feed the powder through the nozzle into this molten pool

- Using the CAD geometric information, CNC controlled head or the bed or both are moved along the build path to creating the metal part feature

Material suitability

Predominantly, DED uses metal in the form of either wire or powder. However, DED technology is also capable of using polymers and ceramics. For example, Arevo makes composite frames using polymer and filament of carbon fibre.

DED supports a wide range of metals as any metal that can be welded can be used to create parts through this technology. Commonly used materials by various manufacturers are as follows;

| Titanium and Titanium alloys | Niobium |

| Inconel 718, 625 | Stainless Steels (300 series) |

| Hastelloy | Aluminium alloy 2319, 4043 |

| Tantalum | Zinc alloy |

| Tungsten | Copper-Nickel alloys |

Typical directed energy deposition applications

DED is already utilised in key industries like aerospace, defence, oil & gas, and the marine industry, for example, aircraft frames and structures, refractory metal components, ballistic material tooling repair and reconditioning and, marine propulsion, etc.

Like any other subtractive manufacturing process, parts made using DED can be heat-treated, hot-isostatic-pressed, machined, or finished in any customary manner, which opens various new applications. Most of the hybrid manufacturing systems use DED and have increased in popularity.

Advantages and disadvantages of directed energy deposition

DED technologies are used exclusively in metal additive manufacturing due to the nature of the process and are ideally suited for repairing or adding material to existing components.

Advantages of DED

- High build rates – DED’s higher deposition rates at relatively low resolution means a faster build rate than other metal additive manufacturing processes.

- Dense and strong parts – DED creates higher-density parts hence their mechanical properties are as good as cast or wrought material.

- Near net shape – Parts can be near net shapes requiring minimal post-processing.

- Can be used for repairing – Ideally suited for application requiring metal addition to existing parts hence lends itself for repairing applications

- Multi-material range – Latest DED machines have the capability to have several different powders or wire containers which enables to build parts with custom alloy

- Larger parts – Comparably larger parts can be built using DED. For example, Sciaky’s EBAM printers have the capability to print parts a few meters high.

- Easy material change – Since the material is fed during the process on demand from separate powder containers, it’s easy to refill or change the material.

- Reduced material waste – DED only deposits the material it needs during the process meaning less wastage compared to processes like powder bed fusion (SLS and DMLS), where the full build platform has to be filled with metal powder

Disadvantages of DED

- High capital cost – Direct energy deposition systems are comparably very expensive to other metal additive manufacturing systems.

- Low build resolution – Parts produced using DED technology are lower resolution with a poor surface finish. It will look like sand or investment castings and require secondary processing such as machining or aqua blasting, adding more time and cost.

- No support structures – Due to how the DED technology builds parts, support structures cannot be used during the build process, hence features like overhangs will not be possible.

No comments:

Post a Comment