This year, Formnext was back. The show returned to a scale and feel not seen since before the pandemic. A lot can be said about the application and technology advances on display this year at the annual Formnext exhibition, but arguably the most noteworthy development out of the show this year was the show itself.

Whereas last year’s Formnext still struggled against travel restrictions, this year’s the show rebounded. According to organizer Mesago Messe Frankfurt GmbH, the event, which ran for four days in November, drew 802 exhibitors (vs. 606 in 2021) across 51,148 square meters of booked exhibition space. And where attendance was under 18,000 last year, Formnext 2022 drew 29,581 attendees.

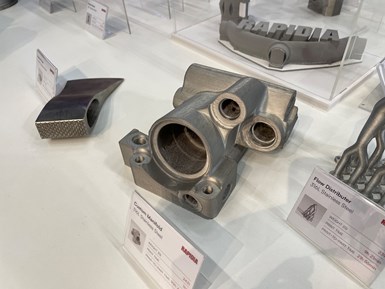

One trend not identified here is the ongoing advance of additive manufacturing for scale production — because this trend is at the heart of Formnext’s theme and focus. Seen here: a 316L stainless steel fuel bypass manifold manufactured for John Deere using HP’s Metal Jet S100 binder jet system.

Held annually in Frankfurt, Germany, Formnext is the world’s leading exhibition focused on additive manufacturing technology. The show’s focus is industrial production, and it offers the single best week of the year for taking in the state of AM’s transformation of industrial production, and observing the next steps this transformation is taking. Our team on Additive Manufacturing Media looks forward to the event each year for just this reason.

The show is so large, it is only possible to spend time with a fraction of the event’s exhibitors. Based on that view, here are 10 trends and developments I saw: 10 important ways AM is either taking new steps or continuing to move forward that were apparent at Formnext this year:

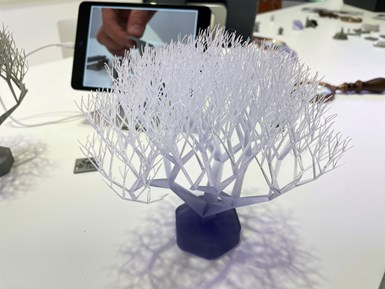

1. The Expanding Reach of Ceramics

This was one of the more defining aspects of the show. I was stuck by how many exhibitors were showcasing advances or solutions in ceramics. We tend to think of manufactured parts being mostly metal or polymer, while ceramic is a more specialized class of material, because metal and polymer are the material types conventional manufacturing processes can most easily work with. But additive changes this — with 3D printing, polymer, metal and ceramic are all practical to apply. This means the valuable material properties of ceramics become more accessible. In the realm of additive, it might be time to recognize that ceramic is a third readily available material category.

Examples:

3D printing on Lithoz’s photopolymer-based platform allowed production of this ceramic pin at over 400 pieces per build.

Lithoz, the maker of 3D printing technology suited to medical implants in various engineered ceramic materials, spoke of 3D printing also as a cost-effective means of mass production for otherwise challenging ceramic components. A part shown, a precision pin-like component used in a demanding application calling upon ceramic’s inertness or heat or chemical resistance (actual details of the application were confidential), was mass-produced at the rate of over 400 per build using one of the company’s ceramic AM machines.- Nexa3D showed ceramic as a tooling material. With high heat resistance and tensile strength, its xCeramic3280 ceramic composite resin (developed with BASF) offers a durable material for 3D printed bridge tooling that, in the case of injection molding, can extend this “bridge” into even large mold quantities than are associated with rapid tooling.

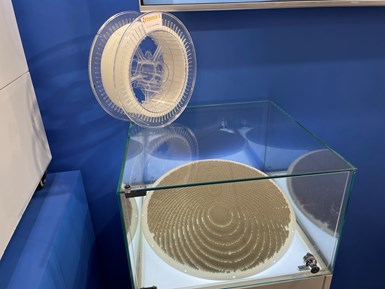

Ceramic material delivered via filament allows for simple FFF 3D printing of complex communications components leveraging the material’s permittivity.

Nanoe’s exhibit and latest offering focused on one useful property of ceramics in particular: permittivity, useful in components for radio communications. The company enables the use of ceramics using polymer filament 3D printers with its Zetamix filament, which carries ceramic material in powder form. Parts 3D printed this way are debound and sintered to created solid ceramic parts. This approach compromises some of the useful properties of ceramics, but where permittivity is the main or sole focus, this doesn’t matter. The result Nanoe is achieving is an efficient means of producing superior-performing communications components.- Clay is a ceramic, too. Wasp showed a 3D printing system for unattended production of vases using continuous feed of the material stock and a shuttle for moving completed vases out of the way of the next build. This system actually captures two trends I saw; I’ll take up unattended production next.

2. Preparing for Unattended Production

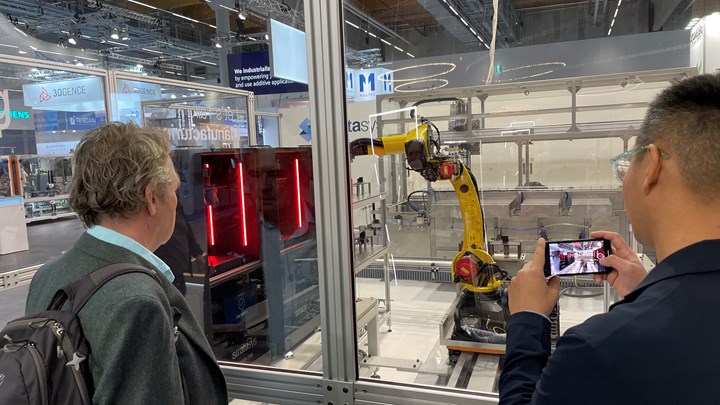

This theme of the show might be expressed as a foretaste or premonition of automation. AM technology providers can see what is ahead: Batch production is the application today; they know they will be called upon to keep that production going by integrating with unattended part loading and unloading tomorrow. They are showing they are ready.

Examples:

- Stratasys offered probably the most prominent example of this at the show. An unattended additive production line on the show floor had a robot tending six different Origin photopolymer 3D printers, with parts conducted from the robot to postprocessing via a conveyor system.

- Boston Micro Fabrication (BMF) is a maker of photopolymer systems for tiny, precise parts — but that means it is inherently a maker of machines for production, because large quantities of the tiny parts can be run in one build. Its new machine seen at the show includes automatic door opening for robot access, again in anticipation of what seems likely to be a coming user need.

- 3D Systems showed a redesign for the frame and structure of its machines. One big change: The mechanics of the machine have been moved to the side so the back of the machine can be opened for robot access.

- Additive Industries, maker of automated modular systems for laser powder bed fusion (LPBF) and related postprocessing, showed a calibration unit in a box that can be loaded into the LPBF build chamber. Incorporating laser power sensing and focus sensing, the unit allows for validating the precision of the laser in a quick calibration run as a seamless part of unattended production, rather than as an independent maintenance step conducted by a technician.

- In discussing its new binder jet system, GE Additive emphasized various process factors in and around the machine, including the role of advanced binder chemistry and accurate modeling of part geometry behavior during sintering — and the potential for automation. The company sees the logical production use case for this technology being build chambers moving automatically between various machines linked to a common depowdering unit that in part recirculates recaptured powder back to machines.

Rivelin has a robotic postprocessing system for metal additive parts that both simplifies programming the robot to machine additive parts and ensures the robot can adapt in real time to machine a dedicated additive part accurately.

UK startup Rivelin is developing robotic technology for effective postprocessing of powder bed fusion metal AM parts. Part of the company’s technology is software — it developed an efficient, intuitive interface to allow the user to quickly program the robot by assigning appropriate metal cutting and finishing tools to different surfaces of the part’s CAD model. Another part of the company’s technology is force sensing. Sensing and responding in real time to subtle movements of the part during finishing allows the robot to use those tools with finesse, minimizing risk of overcutting and scrapping a valuable part.

3. Different Adoption in Europe Versus USA

Two anecdotes illustrate European and American manufacturers embracing additive differently:

This rocket nozzle combining copper alloy CuNiSiCr with Inconel 625 demonstrates the kind of part, spacecraft-focused, that is more prevalent in North American AM applications

A contact at DMG MORI told me happily he had managed to get an American use case into the company’s exhibit of multimaterial 3D printing involving copper. The company was showing a spacecraft part in this exhibit. The commercial space industry is a heavy driver of additive manufacturing in the U.S. The more European application of this multimaterial technology would have been a mold component. A 3D printed mold component making use of copper for thermal conductive was on display nearby, but the spacecraft component in the machine meant the exhibit had an American signature.- A Velo3D leader working to build the company’s sales organization in Europe described a difference he believes he sees between American and European customers. The U.S. user is more likely to be coming to additive from conventional production, and comparing additive to this, whereas the European user is more likely to regard additive and its possibilities, whether favorably or unfavorably, based on some past experience with additive.

Differences such as these are signs of a maturing market. The cultures on different continents have always differed in the ways they apply manufacturing technology. (In machining, for example, I have seen the U.S. and Europe think about five-axis differently for almost my entire career.) If additive use is small, then the only culture is additive users. But when additive’s use is sufficiently big, there is room for cultural differences to define separate experiences within it.

(Speaking of culture, a small memorable moment: At the opening of one of the days of the show, I heard the Velo3D team briefly blaring “California Love” by 2Pac. A nice “America is here” moment from the California-headquartered company.)

4. Successful Platforms Scale Up

AM machines want to get bigger. This is because increased size brings two important opportunities at once: big parts that previously could not be made on the platform, and larger quantities of the kinds of parts the platform is already succeeding with. If a 3D printing platform works, and finds committed users, then likely it will need to scale up. This is not a new development by any means, but there were new examples at the show this year, including:

- Arburg debuted its Freeformer 750-3X, a scaled-up version of the pellet-fed polymer 3D printing system. The machine has a build chamber about 2.5 times larger than the previous large-size Freeformer machine.

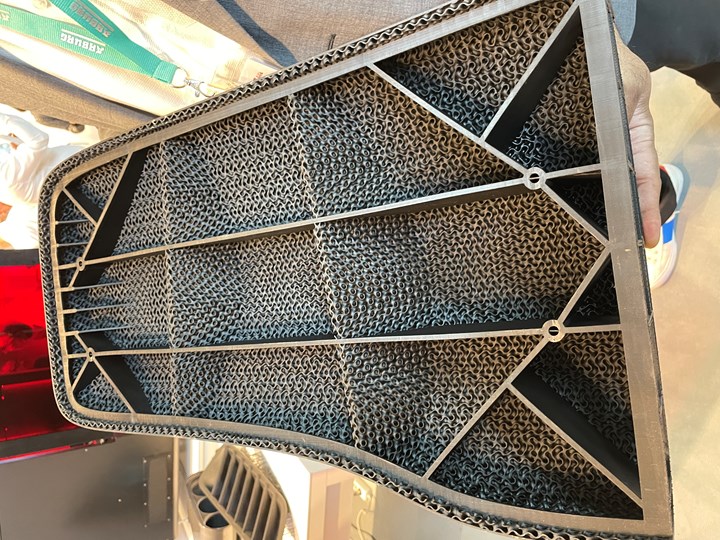

- Photocentric launched its Liquid Crystal Titan, a photopolymer 3D printer with a build volume of 700 × 395 × 1200 mm. For large parts in this machine, Photocentric offers software for converting needlessly thick areas of a part model into lattices to both save material and prevent distortion.

This large component made through DLP was adapted for effective 3D printing using Photocentric software to replace dense solid regions with lattices.

5. Established Companies Entering Additive

This year’s Formnext also seemed notable for the number of companies well established in other areas of manufacturing showing offerings in additive.

Perhaps the most prominent example was Nikon, now expressing its intention to expand into becoming a key provider of AM technology. Earlier this year it introduced a metal AM system and announced its investment in Hybrid Manufacturing Technologies, and then the company came to Formnext after having freshly acquired laser powder bed fusion technology provider SLM Solutions.

Other examples:

- Metalcutting machine tool builder Grob made the Formnext debut of its Liquid Metal Printing system.

- Injection molding machine maker KraussMaffei similarly made the Formnext debut of its deposition-style and stereolithography polymer AM machines.

On this demo piece shown by Otto Fuchs, using DED to produce the most extreme reaches of the otherwise forged part reduces the number of forging tools needed.

Metalforming company Otto Fuchs showed the possibilities for using directed energy deposition (DED) to create the extreme features of otherwise forged parts, reducing the number of dies that a forged (or mostly forged) part requires.- DMG MORI has been in additive for years. But one of its exhibits at the show this year involved seamless transfer of parts from LPBF to CNC machining using a clamping system both machine types share. The clamping interface was developed for AM, engineered for considerations such as sealing against powder. It was developed in conjunction with a company established in workholding for machining, Schunk.

This part was both 3D printed and machined on this plate, which is one-quarter the size of the build plate area in DMG MORI’s LPBF machine. An automatic clamping system on the underside locks four of the plates into the LPBF machine, then locks each plate into the five-axis machining center for postprocessing. Schunk developed this tooling system shared by additive and machining.

6. Wavelengths Show the Way

Across various modalities of AM, much of the work of making solid parts comes down to using light to transmit energy into a material. Material properties figure in — but the light properties are significant as well. The increased possibilities for 3D printing copper that have arrived in recent years are an example of this; existing red lasers operate at a frequency copper mostly reflects, but blue and green lasers permit more energy absorption into copper, and lasers using this wavelength range have been improving in terms of both cost and industrial reliability.

That’s a metal AM example. But the potential utility of optimal light wavelengths for polymer AM, specifically DLP, was apparent in developments at the show this year. Examples:

- Photocentric exhibited DLP as applied to stainless steel. You might note the obvious point: That’s not a polymer! But suspending steel powder in DLP resin provides a means for using DLP to 3D print metal parts. Photocentric’s technology is particularly suited to this, the company says, because the use of long wavelengths in the LCD screens of its machines allows for effective 3D printing despite the energy absorption of a dark material such as metal powder.

Fine precision or speed? A new system from Axtra3D combines both. Stereolithography achieves the fine details while DLP generates the bulk of the form.

Axtra3D introduced a machine that combines two different photopolymer processes, DLP and stereolithography, to realize the speed of the former and the precision of the latter in the same build. In this new system, DLP rapidly cures the area of each layer while stereolithography assures the precision of each layer’s outline and details. The key is wavelength control. The laser performing stereolithography must synchronize with the DLP reaching the edges of the part to ensure that energy input is continuous all throughout each layer, so no difference from two different 3D printing methods manifests in the properties or consistency of the finished part.

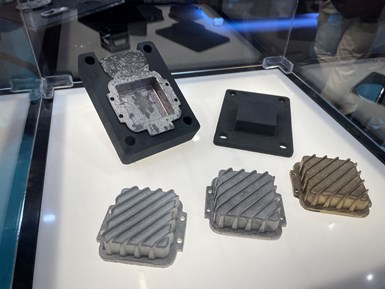

7. The Multi-Front War on Support Structures

Support structures: before and after. The version of the component in the foreground illustrates the build design change resulting from EOS software that seeks to minimize supports by adapting laser parameters to realize unsupported overhangs instead.

The advance of AM systems and technologies — and knowledge — is expanding the range of options for avoiding or minimizing support structures and the extra postprocessing work they entail.

This avoidance begins with design, and therefore begins in software. EOS showed a preview of a plugin for Autodesk software that allows for the control of supports in 3D printed parts made on EOS machines. In some cases, control over build parameters in the region of a part’s overhang feature can take the place of support structures, allowing the feature to be printed effectively without any need for supports to secure it. That capability figured into various low- or no-support parts shown in the EOS booth.

3D Systems sees something similar. Allowing support structure tactics to advance more quickly is an aspect of why the company allowed its software offerings to shift to a separate company not tied to one 3D printer maker. 3DXpert software once associated with 3D Systems is now part of Oqton. Among other things, the software provides for snap-off support structure design drawing on knowledge 3D Systems developed through both polymer and metal AM.

But the hardware plays a role, too. Two intriguing examples at the show this year:

- The Fraunhofer Institute (Fraunhofer IWU) and Metrom showed a parallel kinematic machine for deposition-style polymer 3D printing. The machine’s five-axis table motion allows for orienting the part at just the right angle at every moment so that supports against gravity may not be needed, and the use of a parallel kinematic platform to achieve this allowed for the five-axis motion to be performed both precisely and rapidly. See video below.

This 3D printer design uses the nozzle as support. Two simultaneously printing nozzles include one that prints from below and supports the part as it does.

German startup Duplex showed a machine that 3D prints from above the part and below at the same time. The lower 3D printing head is an answer to supports because it essentially is the support structure; the nozzle itself supports overhanging features are they are being produced.

8. 3D Printing Accelerating Casting

Additive manufacturing is providing an alternative to casting for many parts; it offers a means to obtain near-net-shape metal components without resorting to tooling or a metal foundry. But another promising avenue is reconsidering casting by incorporating additive manufacturing into the process.

The Foundry Lab process involves 3D printed ceramic molds. Metal is placed into the mold in solid slug form like depositing a large coin in a slot.

Foundry Lab showed an intriguing example. The company’s Digital Metal Casting process begins using binder jet 3D printing to mass produce ceramic molds. A microwave oven sinters these molds. Then, each mold is filled not by pouring liquid metal (typical of casting), but instead by placing a metal slug inside — a disk of the metal required (aluminum and zinc are available today; other metals are coming), provided by Foundry Lab. The mold then goes back into the same microwave oven, where the ceramic focuses the energy of the microwave to melt the slug and create the final cast part. The result is casting relying on 3D printing, with no traditional foundry involved and no need to handle molten metal.

The Massivit casting process involves 3D printing a sacrificial mold and pouring in liquid resin as the mold is being printed. A solid form results when the 3D printed tool is dissolved away in water.

Massivit demonstrated its option for casting large forms made of non-metallic materials. The company’s Cast-in-Motion AM system involves 3D printing large shells with a water-breakable thermoset, with epoxy material poured into the shell as it is being printed. The epoxy solidifies, and the 3D printed shell is removed by dissolving it in water. The system provides a rapid means of produce large tooling for composites, and the company is experimenting with other types of materials that can also be applied through casting using this 3D printed sacrificial tooling.

9. The Deployability Opportunity

A recurring theme that came out in conversations with exhibitors is the extent to which the military’s desire to bring manufacturing into the field or closer to the point of use was creating new opportunities. Additive is a distinctly self-contained and therefore deployable manufacturing option, so it makes sense that this aim of the military logistics community is finding its way to AM.

Examples:

Rapidia’s metal paste 3D printing process provides a fast and relatively simple means of obtaining metal replacement parts in the field.

At Formnext this year, Rapidia was “back” even though it never left. A distribution agreement with ExOne created the impression it was affected by ExOne’s acquisition last year by Desktop Metal — but the startup remained independent all along. The company says one area of interest in its technology it has seen is for military uses involving transporting the printer. Rapidia’s 3D printing method involving metal paste (which we first saw in 2019) offers a particularly easy method for obtaining small quantities of small metal parts.The newest model of Essentium’s high-speed FFF machine is an industrial system that navigates non-factory settings. One of the engineering considerations is machine dimensions allowing it to fit through standard doorways.

Farther from the field, but at a more advanced level of speed, part value and adoption, Essentium described its success at finding a similar role. The company offers a high-speed, open-architecture, industrial-precision, deposition-style 3D printing system that is increasingly finding success in military sustainment applications. An example on display was a military aircraft duct replacing a legacy part formerly made of sheet metal. Relying on an AM platform such as this for sustainment brings new options for part-making nearer to the military’s point of use, including on ships.

10. Advancing Sophistication for DED

This solid DED part was presented as the largest 3D printed pressure vessel in Europe. It was manufactured by Andritz Savonlinna Works Oy and displayed by FAME, the Finnish Additive Manufacturing Ecosystem.

Directed energy deposition is a capability to watch. That might seem strange to say, since DED is the oldest metal AM capability, and seemingly the simplest. It consists of applying depositing metal in layers, and building by welding.

But there is greater capability and control being won for DED, and examples were on display. Here are some:

- German startup Ponticon showed its high-speed DED system relying on a parallel kinematic platform to move the table beneath the deposition head. It is no accident that parallel kinematic motion is appearing in this article for the second time. Additive is not a force-limited process, so the opportunity exists for efficiency gain by moving faster. Compared to a more traditional machine motion system, a parallel kinematic system allows for precision motion at greater acceleration.

- Hexagon spoke of the promise that improved programming will bring to DED. Specifically, simulation. DED can realize greater precision by employing simulation as a programming tool, and the company is working to advance this idea. There is already precedent, the company notes. In welding, programmers rely on simulation to predict hot spots. DED can benefit from programming using predictive simulation the same way.

Bonus Development: 3D Printing Wood

An ornate guitar body 3D printed using Desktop Metal’s Forust system for binder jetting with wood. (I don’t play, but at AM trade shows I seem to end up holding guitars from time to time.)

I’ll call this a trend because I encountered it twice at the show. Among the materials Massivit is learning to apply using its AM system, one of the samples on display was a part made of wood.

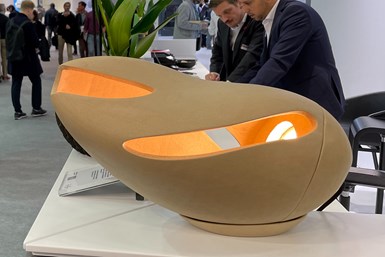

Lamp manufacturers are among the potential users for 3D printing in wood.

But the exhibitor that had a fully developed solution in this area was Desktop Metal, which showcased its Forust system for 3D printing wood. For this system, Desktop Metal provides not just equipment and software, but also material derived from maple and oak waste. Establishing a reliable source of supply for raw material for wood 3D printing was one of the needs the company faced in developing this platform. The Forust system 3D prints in wood via binder jetting, with printed parts needing only to cure after the 3D printing. One promising potential user is the lighting industry, the company says, because of the greater range of design possibility the capability brings to lamps.

I began this piece with a broad note about materials, and how ceramics had arrived as a third material category accessible to AM, and in the future, we might think of wood as a fourth.

No comments:

Post a Comment