To make it simple, a scramjet is a supersonic combusting ramjet). This is a variant of a ramjet jet engine in which combustion takes place in supersonic airflow.As Scramjet is essentially a Ramjet with variations, it would be easy if we start our learning process from Ramjet. Let’s first start with the basics – the difference between a jet engine and rocket engine.

What is the main difference between a Jet and Rocket engine?

The main difference is that a rocket carries its own supply of oxygen (Oxidizer Tank) for combustion while a jet engine utilizes oxygen from the atmosphere for combustion. This makes rocket engine less energy efficient when compared to Jet engines.

Jet Engine

A jet engine is a machine that converts energy-rich, liquid fuel into a powerful pushing force called thrust. The thrust from one or more engines pushes a plane forward, forcing air past its scientifically shaped wings to create an upward force called lift that powers it into the sky.

The first operational Jet Engine was developed by Hans von Ohain of Germany. But the credit for its discovery got to Great Britain’s Frank Whittle (1930).

The main processes in a Jet Engine

A Jet Engine has 3 main processes:

1. COMPRESSION

It increases the pressure of the air trapped inside the chamber.

2. COMBUSTION

It increases the temperature of the air-fuel mixture by releasing heat energy from the fuel.

3. EXHAUST

It increases the velocity of the exhaust gases, thereby powering the vehicle.(Newton’s third law of motion)

Types of Jet Engines

All jet engines and gas turbines work in broadly the same way. Hence they all share five key components: an inlet, a compressor, a combustion chamber, and a turbine (arranged in exactly that sequence) with a driveshaft running through them. Even though they have similarities, jet engines differ in their extra components. The main types of Jet engines based on how air is compressed in the engine are as below:

All jet engines and gas turbines work in broadly the same way. Hence they all share five key components: an inlet, a compressor, a combustion chamber, and a turbine (arranged in exactly that sequence) with a driveshaft running through them. Even though they have similarities, jet engines differ in their extra components. The main types of Jet engines based on how air is compressed in the engine are as below:

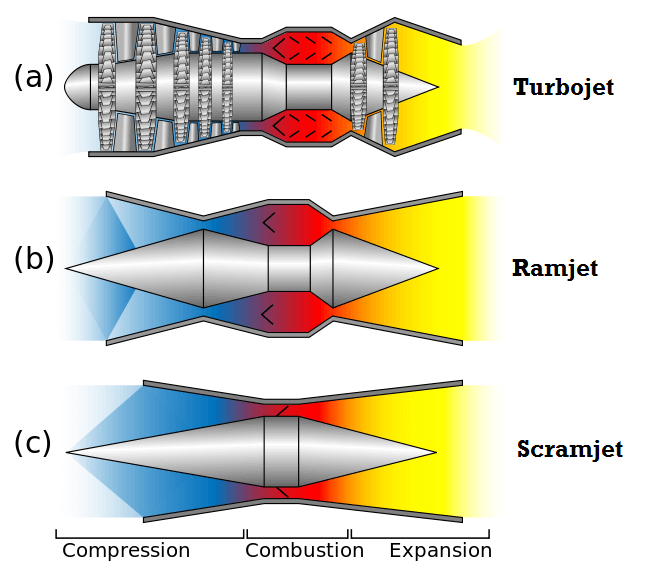

1. TURBO JET

Turbo jet engine is an air-breathing jet engine. This is one of the most common types of jet engines. It is still widely used in airplanes.

2. TURBOFAN ENGINES

Turbofans differ from the turbojets in the way they have an additional component – a fan. The fan sucks in the air and then further gets compressed and combustion takes place in the burner.

3. RAMJET

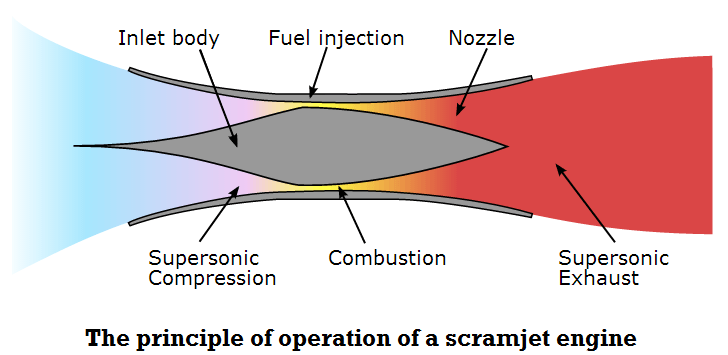

High-speed forward motion is used to compress the air (no compressor). Fuel is injected into the combustion chamber where it mixes with the hot compressed air and ignites. The average speed of Ramjet is 3-6 Mach. But the ramjet efficiency starts to drop when the vehicle reaches hypersonic speeds.

4. SCRAMJET

Here also, the high-speed forward motion is used to compress the air (no compressor), but it is an improvement over the ramjet engine as it efficiently operates at hypersonic speeds and allows supersonic combustion. Speed is greater than 6 Mach (Six times the speed of Sound).

5. DUAL MODE RAMJET (DMRJ)

Type of jet engine where a ramjet transforms into scramjet over Mach 4-8 range, therefore, it can operate both in subsonic and supersonic combustion modes.

Scramjet (Supersonic Combustion Ramjet): Operation Details

- To fire something we need air, that is oxygen. Rockets usually carry oxygen in oxidizer tank even when it is traveling in earth’s atmosphere. But, if we can use atmospheric oxygen during this time it would become energy efficient. Here comes the importance of Scramjet engine.

- Scramjet engine designed by ISRO uses Hydrogen as fuel and the Oxygen from the atmospheric air as the Oxidizer. This makes the system much lighter, more efficient and cost effective.

- The scramjet engine was test launched on board of Rohini 560 sounding rocket (Research Rocket). This RH 560 is a two stage Advanced Technology Vehicle (ATV) and is designed & developed by ISRO to test scramjet engine. ATV is the heaviest (3 tons) sounding rocket developed till date by the ISRO.

India and Scramjet Technology

India had started the efforts on Scramjet technology long back and we did a ground testing in 2006 which validated the design of the engine. And now, India became the fourth country to claim the successful testing of Scramjet Engine. Russia was the first country who claimed scramjet flight test in 1991, and later US and European Space agency also joined the elite group.

Scramjet – Challenges

- As mentioned earlier, Scramjet does not have a compressor to compress the air, instead, it uses its high-speed forward motion to compress the air. Therefore scramjet cannot produce efficient thrust unless boosted to high speed. From this, we understood that scramjet engine cannot work until it attains enough speed. This is the main drawback of Scramjet Engine.

- As we all know, Launch Vehicles have multiple stages with each having a different engine. After the fuel burns out in the first stage, the engine is jettisoned to reduce the weight of the vehicle. So when the second stage ignition begins, speed is enough for the scramjet to function. Therefore ISRO used scramjet engine at the second stage during the flight test and using this technique it excelled in overcoming the drawback.

- Some of the other technological challenges handled by ISRO during the development of Scramjet engine include the design and development of Hypersonic engine air intake, the supersonic combustor, development of materials withstanding very high temperatures, computational tools to simulate hypersonic flow, ensuring performance and operability of the engine across a wide range of flight speeds, proper thermal management and ground testing of the engines.

The importance of having this technology

- The efficiency of the launch vehicle depends on how much weight it can carry for with a particular amount of fuel. Currently, Indian rockets carry a huge quantity of oxygen (approx.200 tons) that is nearly 85 percent of the rocket mass and it gets burnt during the atmospheric flight phase of the rocket. Use of Scramjet would help to reduce the weight of launch vehicle and increase the speed. It would help India to do more with a limited space budget.

- Satellite launching business is gaining momentum and Antrix Corporation (the Commercial wing of ISRO) has been launching satellites at a lower cost when compared to other players. This can be further augmented by using Scramjet Engine which would help to minimize the cost.

- Scramjet engine can be used to augment ISRO’s reusable launch vehicle (RLV).

Avatar

Avatar (from “Aerobic Vehicle for Transatmospheric Hypersonic Aerospace TrAnspoRtation”) is ISRO’s reusable launch vehicle platform which is capable of carrying out satellite launches like normal aircraft, takes off vertically and lands back on a runway. It is designed to use ramjets and scramjets for thrust. Each of these engines will be used in different stages of the flight wherein scramjets are used at hypersonic speeds.

Summary

In a nutshell, development of Scramjet engines is an important milestone in ISRO’s endeavor towards its future space transportation systems. Air breathing propulsion is a solution for a powered long return cruise flight necessary for reusable launch vehicles. In addition to this, DRDO has been working on to develop Brahmos II Cruise Missile based on the same scramjet technology. This calls for the faster development of ramjet or scramjet technologies which would help India to execute advanced space missions in future. Also, it will add colors to our much hyped Make In India initiative.

No comments:

Post a Comment