What is a Pulley?

A-Pulley is a simple mechanical device that we encounter in our daily life and is used for transmitting power. A pulley consists of a wheel that is mounted on an axle or a shaft, this wheel can be driven by a chain, belt, rope, etc.

Pulleys are generally used for changing the direction of the force and decreasing the amount of input force. You may observe a pulley inside the elevators, in the gyms, on construction sites, etc.

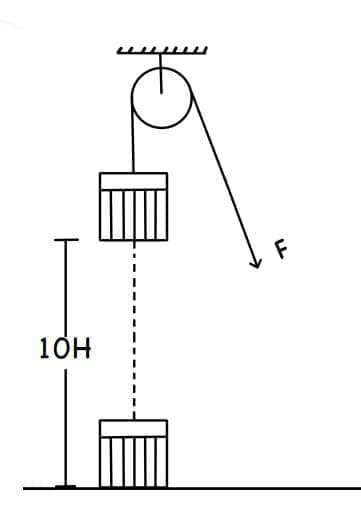

Pulley Example:

Consider that a barrel kept on the ground is to be lifted to the ceiling above by 10ft from the ground level.

In this case, we can simply apply a pulley to the ceiling and simply change the direction of the applied force as shown in the figure.

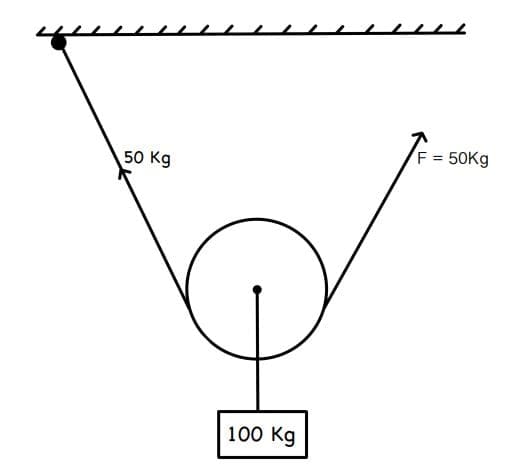

Now, consider a block of weight 100kgs to be lifted above the ground. Now the pulley is placed in such a way that the force is evenly distributed between each side of the rope by half of the weight of the pulley. hence the input force is reduced by half.

History of Pulley:

The existence of pulleys was evident in 1991 -1802 BCE in ancient Egyptian civilization.

Evidence of pulleys is also found in Mesopotamia in the 2nd millennium BC. Roman hero Alexandria also identified pulleys as an important simple machine.

Working principle of a Pulley:

A pulley works on the principle of conservation of energy. According to the principle, work done on either side of the ring must be equal.

Mathematically it is written as F1d1 = F2d2.

The direction of the output force in the case of a pulley is changed by the ring. The direction can be manipulated by the designer of the pulley.

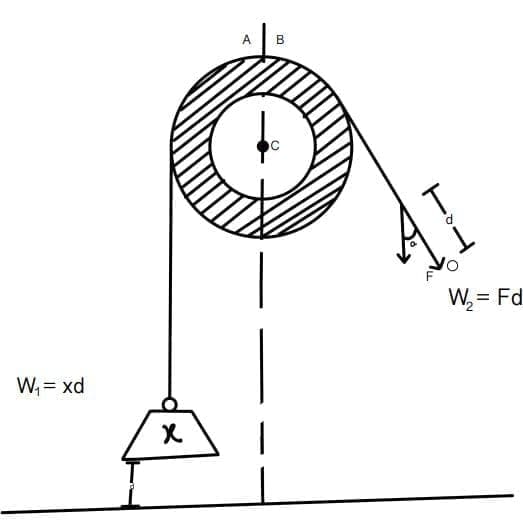

For example:

Consider a pulley system in which a mass x kg is to be lifted. The whole area is divided into 2 parts, part A is for work output and part B is for work input.

Let I be the initial point and O be the final point and F is the input force. It can be observed that if d is the same and W1=W2 then the input force F will be the same as x. as far as the direction of force is concerned it is also changed by an angle Q in the negative direction.

Mathematically:

- W1 = W2

- Xd = Fd

- Hence, X = F

Pulley Basic Construction:

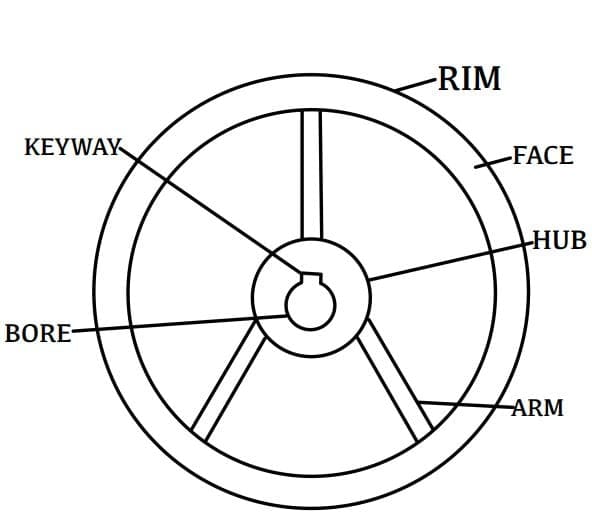

A pulley consists of a circular disc with a given thickness.

The outermost part of the disc is called the rim of the pulley.

The elements such as rope, chain, or belt are mounted on the face of the pulley rim.

Inside the rim, there are supporting elements called arms.

An arm may resemble the radius of the circle. There are generally 3-4 arms in a pulley. Arms may be absent in some of the pulleys, making it a simple solid structure.

The inner circular structure is called a hub and inside the hub, there is a borehole with a keyway. The key is an important element for the transmission of power.

Types of Pulleys:

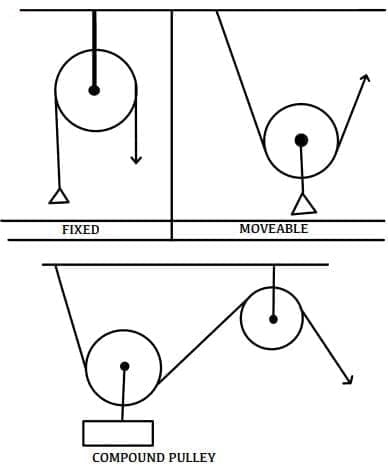

Fixed Pulleys:

When the axle of the pulley is fixed at a single position it is called a fixed pulley.

A fixed pulley is generally used to change the direction of the force. A fixed pulley is the simplest form of a pulley.

The best example of a fixed pulley is the pulley attached to the well for removing water from the well.

Fixed pulleys are used to lift light weights as the force that should be applied to lift the weight is equivalent to the weight of the object to be lifted.

Movable Pulley:

When the axle of the pulley is allowed to move it is called a movable pulley.

A movable pulley is supported by a single rope around the face of the pulley. The rim of a movable pulley moves with the weight of the object to be lifted.

There is no change in the direction of the force in a movable pulley but the magnitude of the applied force is reduced to half.

This results in reduced efforts by the operator. It can be concluded that a movable pulley makes the weight feel much lighter but the direction of the force remains the same.

Compound Pulley:

As the name suggests a compound pulley is a combination of a fixed pulley and a movable pulley.

In this type of pulley, the applied force is reduced, which means that the object feels to be much lighter than its original weight.

As well as the direction of the force is also changed. In the diagram given below pulley, A is a movable pulley that reduces the force by half and the pulley B is a fixed pulley that is used to change the direction of the force.

A compound pulley is used in many construction sites to lift heavyweights.

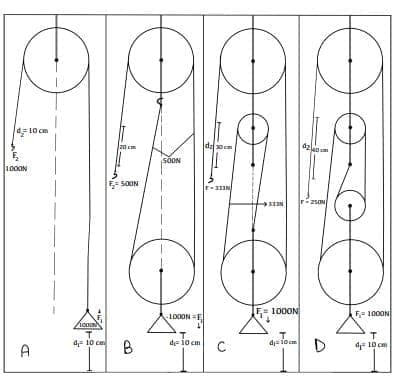

Block and Tackle Pulley:

Block and tackle pulleys are important types of compound pulleys.

In the above case of compound pulley one fixed and one movable pulley are attached to form a compound pulley which may reduce the force by half.

But if the object is very heavy the above type of compound pulley may not function properly.

Hence an arrangement is made in which different fixed and movable pulleys are used in a parallel set up to reduce the force and change the direction of the force.

In the diagram given below, there are 3 arrangements of block and tackle pulley.

The applied force can be found by the equation W1d1 = W2d2

Figure A represents a simple fixed pulley in which the force and distance are the same.

In figure B there is one fixed and one moving pulley; this reduces the force by half but increases the distance to double.

And In figure C there are two fixed and one movable pulley, this reduces the force by 1/3 and triples the distance.

Whereas In figure D there are two fixed and two movable pulleys, in this case, the force is reduced by 1/4 and the distance is increased four times the lift.

It can be concluded that the force is reduced by the number of pulleys. Hence the applied force can be written as F/n. Where n is the number of pulleys in a block and tackle pulley.

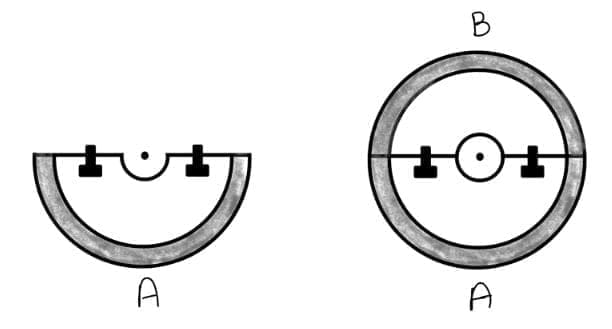

Split Pulley:

A split pulley is a type of pulley that is divided into two parts which are clamped with nuts and bolts.

These pulleys are used for power transmission from a complex shaft where mounting of simple pulley may get difficult.

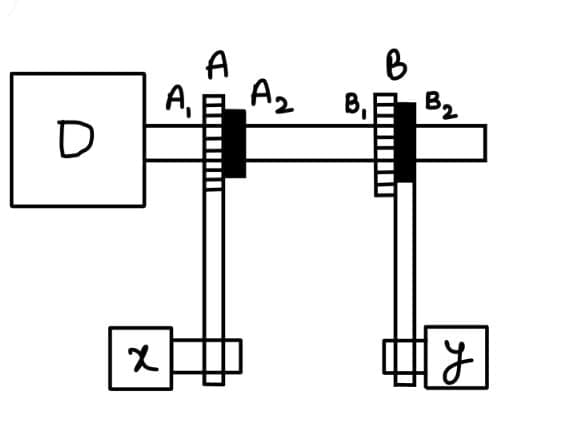

In the given figure A and B are two halves of a split pulley. These can be placed on the shaft by loosening the nuts and then again fastening them for the proper functioning of the pulley.

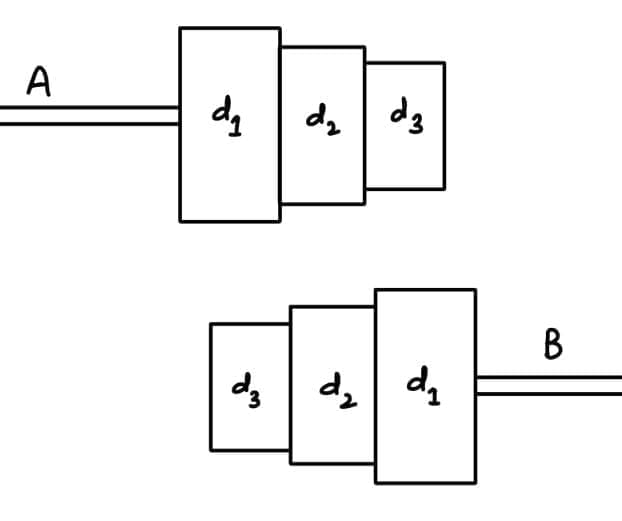

Step or cone Pulley:

Step or cone pulley is another important type of pulley which is used for variation of speeds.

As the name indicates, a step pulley consists of various rims of different diameters. These are generally used in bicycles and lathe machines for varying speeds.

In the figure given let’s say A is the driving shaft and B is the driven shaft. The diameter of the step pulley is d1, d2, and d3.

1. If the belt is on d1 on the driving pulley and d3 on the driven pulley then the speed will be maximum. This is because d1>d3 hence for one rotation of A there will be more rotations of B.

2. If the belt is on d2 on both the pulleys then the speed of A and B will be equal because d2=d2.

3. If the belt is on d3 on the driving pulley and d1 in the driven pulley then the speed of B will be less than that of A because d3<d1.

Loose and fast Pulley:

A loose and fast pulley is a pair of pulleys in which one pulley is attached to the shaft and the other one has a bearing to move freely.

This type of pulley is used where one shaft is used to drive more than one system.

In the given diagram A and B are the two pulleys with A1 and B1 being attached to the shaft and A2, B2 has bearings to move freely. D is the main driver, and x and y are the systems to be driven. Now the number of cases may occur.

1. If the user wants the only x to function, he will simply put the belt of x on A1 and the belt of y on B2. In this way only x will function and y will stop as B2 won’t rotate due to the bearing present in the pulley.

2. If the user wants only y to function, he will put the belt of x on A2 and the belt of y on B1.

3. In the same way if he wants both to function, he will put both the belt of x and y on A1 and B1 respectively.

Jockey Pulley:

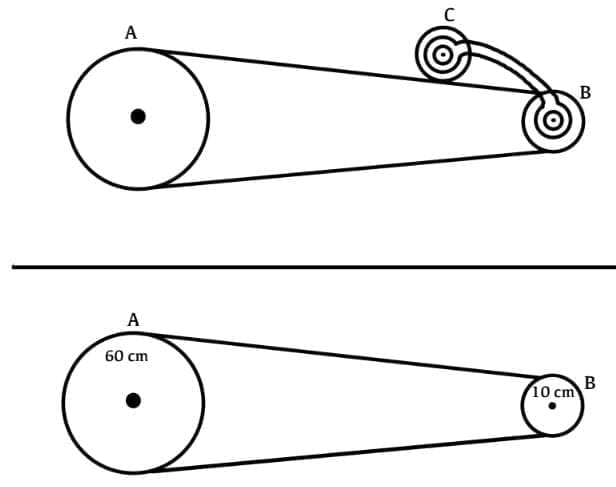

When two pulleys are working together and the diameter of one is quite more than the other one ( the diameter ratio is more than 6:1).

In such a condition the contact between the rope and the smaller pulley is very less. This results in a slipping condition between the pulley and the belt.

Hence another pulley called a jockey pulley is introduced in order to increase the contact area between the pulley and the belt. When C is introduced the contact area of the belt with B increases.

Attachments used on Pulley for transmitting forces:

Various attachments can be used on a pulley for transmitting force. Some of the basic attachments are as follows.

Rope:

A rope used on a pulley can be as simple as a jute rope or as strong as a metal rope.

Depending on the application of the pulley and the load to be lifted, the strength and flexibility of the rope may vary.

The most common example of a rope pulley is the pulley attached to the well for extracting water. The pulley used with rope is generally a half-round pulley.

Belt:

A belt on a pulley is quite common in many machines. The Belt used on a pulley can be made of rubber or any synthetic material for better grip.

The shape and size of the belt also vary according to the applications. For example- a V belt with a V curved pulley is used for the transmission of high loads. A belt pulley is generally used in lathe machines.

Chain:

A chain pulley is generally used when the weight of the object is high. This is because minimum chances of slipping take place in a chain pulley.

A chain pulley has grooves on the rim of the pulley so that the chain fits the pulley and force transmission takes place.

Note:- a chain sprocket is a disk with teeth on which the chain is attached while a chain pulley is a wheel with some teeth, which is used to lift heavy loads.

Materials used for making Pulley:

Several types of metals and non-metals can be used for making pulleys having different applications. Some of the important materials used for making pulleys are given below.

Cast iron:

Cast iron is the most widely used metal for making pulleys. It is easy to manufacture a pulley using cast iron as a raw material.

Cast iron pulleys are cheaper than the other pulleys as the raw material is cheap. A cast-iron pulley is generally brittle and hence cannot take variations in loads.

The durability of cast iron is also less; the surface is easily attacked by corrosion when exposed to moisture.

Steel:

A pulley made of steel has better strength and durability when compared to a cast-iron pulley. But the cost of a steel pulley is more than that of a cast-iron pulley.

It is also lighter in weight; the weight of a steel pulley is almost half of that of a cast-iron pulley.

A steel pulley is generally provided with a bush in the center and there are no keyways provided.

Stainless steel:

A stainless-steel pulley is used for marine applications, as it won’t rust easily.

The saltwater environment may easily corrode the pulleys made up of steel, hence stainless steel proves to be a convenient replacement.

The cost of these is somewhat higher than that of the steel pulleys. A stainless-steel pulley is used with a chain for lifting the anchor of the ships.

Wood:

Wood was a widely used material for making pulleys before metal pulleys came into existence. Many of the Viking ships used wooden pulleys for hoisting the sails using a rope.

This Pulley is much lighter in weight than cast iron pulleys. These are often coated with a layer of water-resistant material to keep them away from moisture.

The wooden pulley is made of selected quality wood. It has a hub made of iron with a bush used for clamping the shaft.

Plastic:

Pulleys are also made of thermoplastic materials and have very few industrial applications.

A plastic pulley is generally used for lifting very light weights.

It can be observed commonly in plastic toys. Manufacturing plastic pulleys are very simple because plastic is easy to mold.

Applications Or Uses of Pulley:

- Pulleys have endless applications in various mechanical devices, so many applications cannot be listed down. Hence, the following are some important applications of pulleys.

- The most common application of a pulley can be observed in an elevator in our daily life. It uses a multiple pulley system to provide a vertical lift.

- The use of pulleys can be observed in rural areas for extracting water from deep wells.

- Pulleys are also used on construction sites for lifting heavyweights.

- Pulley systems are also commonly used in many gym equipments.

- A pulley is also used for hoisting flags. As it is difficult to reach the top of the pole.

- Pulleys are also used in ships for lifting the anchors as well as to hoist the sails.

- A pulley system is also used in theatres for closing and opening the curtains.

- Construction cranes also use a pulley system to lift the objects.

Advantages of Pulley:

- The effort of positioning the weight to be lifted is reduced.

- It reduces the force to be applied to lift a heavy object ( in case of multiple pulleys)

- It changes the direction of the applied force.

- The process of lifting becomes faster.

- Pulleys may prevent injury while lifting heavyweights.

- Maintenance is easy.

- Assembly and disassembly are also convenient.

Disadvantages of Pulley:

- There are chances of slipping as friction is involved.

- Pulleys are not suitable if the RPM is very high.

- If the angle of the rope w.r.t the pulley is increased, it may slip out from the pulley.

No comments:

Post a Comment