Industry 4.0 is the next step in our global, digital, manufacturing and industrial evolution.

The human race is constantly, inevitably, innovating, and the last few years have seen some of the most significant leaps in digitisation in a generation.

But this “invention”, amongst many others, is simply the most recent iteration within what we now call Industry 4.0, or the fourth industrial revolution – the manufacturing industry’s continual, worldwide, multi-faceted evolution. The payoff of these great leaps in manufacturing output and product are new ways to work, create, live, provide food and energy, manage the economy, socialise, and keep people healthy.

Photo by Rob Lambert, on Unsplash.

Photo by Rob Lambert, on Unsplash.

As discussed below, every generation has had its evolutionary “moment” – a creation or invention that shifts the manufacturing industry status quo, opening up new avenues of possibility. Those inventions point to a change in how we live and perceive progress and typify each industrial revolution.

Think about the steam engine, the assembly line, nuclear power, and air travel – all indicative of a new normal, a new way of living and working that changed the trajectory of humanity, and all driven from the workshops and engine rooms of manufacturers worldwide.

We are now between Industry 3.0 and 4.0 – indeed, we’ve already leapt.

The development of AI systems brings AGI closer. But for the layperson, what on earth is Industry 4.0 and the fourth industrial revolution, how does Industry 4.0 differ from the previous generation, and why does it matter that we label these industrial ages as such?

We can see the rhythms of history within each age and learn from how macro-changes affect people to ensure our next industrial revolution doesn’t leave anyone behind.

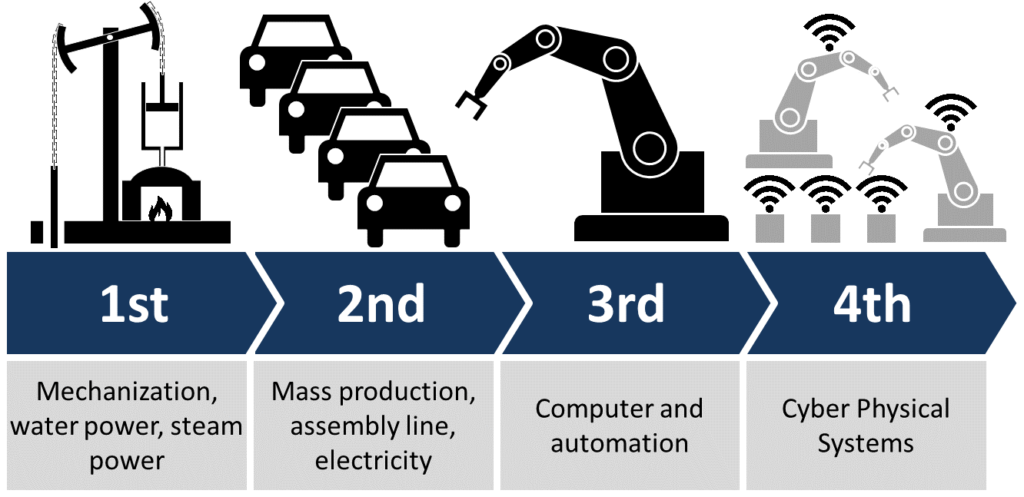

How Industry 1.0 Became Industry 4.0

Here is a visualisation of the different stages of industrial production and where we find ourselves in 2023, staring over the precipice of a new dawn of computing, cyber-physical systems, AI and new forms of industrial production.

Image Credit: “Christoph Roser at AllAboutLean.com “

What Was Industry 1.0?

Industry 1.0 refers to the first industrial revolution – a period from the mid-18th century to the end of the 19th century typified by the emergence of mechanised manufacturing and industrial output.

Think steam power, coal power, the first factories, the rise of factory-centric cities and the beginnings of mass movements of labour and investment into urban areas and areas of high industry production.

Early signs pointed to significant improvements in living conditions, sowing the seeds for the age of mass manufacturing. But it was an era beset by inequality, poor safety standards, child labour, the continuing blight of slavery and chattel labour, the rise of Empires and significant, destructive asset stripping from the Global South and East.

What Was Industry 2.0?

Industry 2.0 was the era of mass production – the assembly line, the centralisation and monopolisation of manufacturing and the end of specialist cottage industries, all powered by a new piece of world-changing tech – electricity.

Unsplash+In collaboration with Getty Images

The perfect exemplar of Industry 2.0 was the Car – the ideal amalgamation of assembly line efficiencies, new technical power, rapidly delivered infrastructure, total supply chain and labour control, and rising customer investment and capital spending. Other notable inventions – such as nuclear power – are also pillars of Industry 2.0, as was the significant shift of money, power and influence to the West via supra-national organisations like the UN and NATO. Industry 2.0, though, can also be considered the age of the World War. Industrialised forms of warfare brought untold suffering to hundreds of millions worldwide in the mid-20th century, and from the assembly lines of our war economies rolled the new tools of power – the atom bomb, nerve agents, drones and biological weapons.

What Was Industry 3.0?

The third industrial revolution was what we now call the Digital Revolution – this incorporated the rise of the computer, robotic manufacturing, email, the Internet, automation and the emergence of cloud computing and software-led efficiencies, brought to life at the end of the 20th century.

Other consumer-focused creations also define the third industrial revolution, like cheap air travel, social media, the rise of the mobile phone, the electric Car, and the production of renewable energy.

But from the other side of the revolutionary coin emerge uniquely 21st-century dysfunctions – the erosion of trust in public and social institutions by the rise of alternative truths generated online, insecure global supply chains that wither under stress, vast wealth hoarding by the super-rich, and the slow trickle of new forms of mass migration – not to mention the rising spectre of water shortages and food insecurity – as the climate crisis starts to tighten its grip.

What Makes Up Industry 4.0?

- “The fourth industrial revolution will take what began in the third, with the adoption of computers and automation and enhance it with smart and autonomous systems fueled by data and machine learning”.

Unsplash+In collaboration with Getty Images

Industry 4.0 is where our physical and digital worlds combine – the typical Industry 4.0 standard bearers of progress, are the Internet of Things, Artificial Intelligence, Machine Learning and Big Data, and how these creations intersect with human networks and industrial capability worldwide.

In short, Industry 4.0 optimises what happened in Industry 3.0 by creating more interconnectivity and decentralisation between cultures, knowledge centres, manufacturers and users.

Of course, the future of Industry 4.0 and the move to Industry 5.0 still needs to be discovered. The incredible changes that have come about in manufacturing in the 21st century are now firmly driven by digitisation and efficiencies generated as a result. They impact everything, from manufacturing processes to principles and technologies, not to mention how manufacturing is powered, delivered, used or understood.

Although the future is uncertain, the groundwork is already in place for a period when digital networks and online fiction will be the rule rather than the exception.

Here are some noteworthy illustrations of how our environment is altering and the direction that evolution is taking:

Big Data

“Big data can be described as data management challenges that – due to increasing volume, velocity and variety of data – cannot be solved with traditional databases.

Unsplash+In collaboration with Getty Images

A sound big data strategy can help organisations reduce costs and gain operational efficiencies by migrating heavy existing workloads to big data technologies, as well as deploying new applications to capitalise on new opportunities”.

Big data is the fuel of business success in the future. But with the increasing digitisation of everything from supply chain management to manufacturing production data to customer data, manufacturers have never been as plugged into real-time product use as they are now.

This interconnectivity means decision-making is improved, customer service is made more immediate and relevant, production transparency is made better, and, above all else, inefficiencies are visible.

In short, manufacturers are leading a new culture of hyperreactive, agile product creation by collating, analysing and using Big Data to improve services.

Advanced Analytics

“Advanced Analytics is the autonomous or semi-autonomous examination of data or content using sophisticated techniques and tools, typically beyond those of traditional business intelligence (BI), to discover deeper insights, make predictions, or generate recommendations”.

Hand in hand with Big Data, advanced analytics are driving businesses into new, data-led efficiencies. An example would be a car maker getting live data from their online configuration tool and analysing it to suggest profit maximisation actions.

Unsplash+In collaboration with Getty Images

Machine Learning

“Machine learning is a branch of artificial intelligence and computer science which focuses on using data and algorithms to imitate how humans learn, gradually improving its accuracy”.

Machine Learning allows computers to learn new things independently, without relying on pre-programmed algorithms to complete tasks or iteratively know how to do certain functions, significantly increasing its utility in all processes.

Some examples include facial, image and speech recognition software, all of which learn as the systems scan and interpret data in real-time, providing analysis or more accurate data parsing with more data.

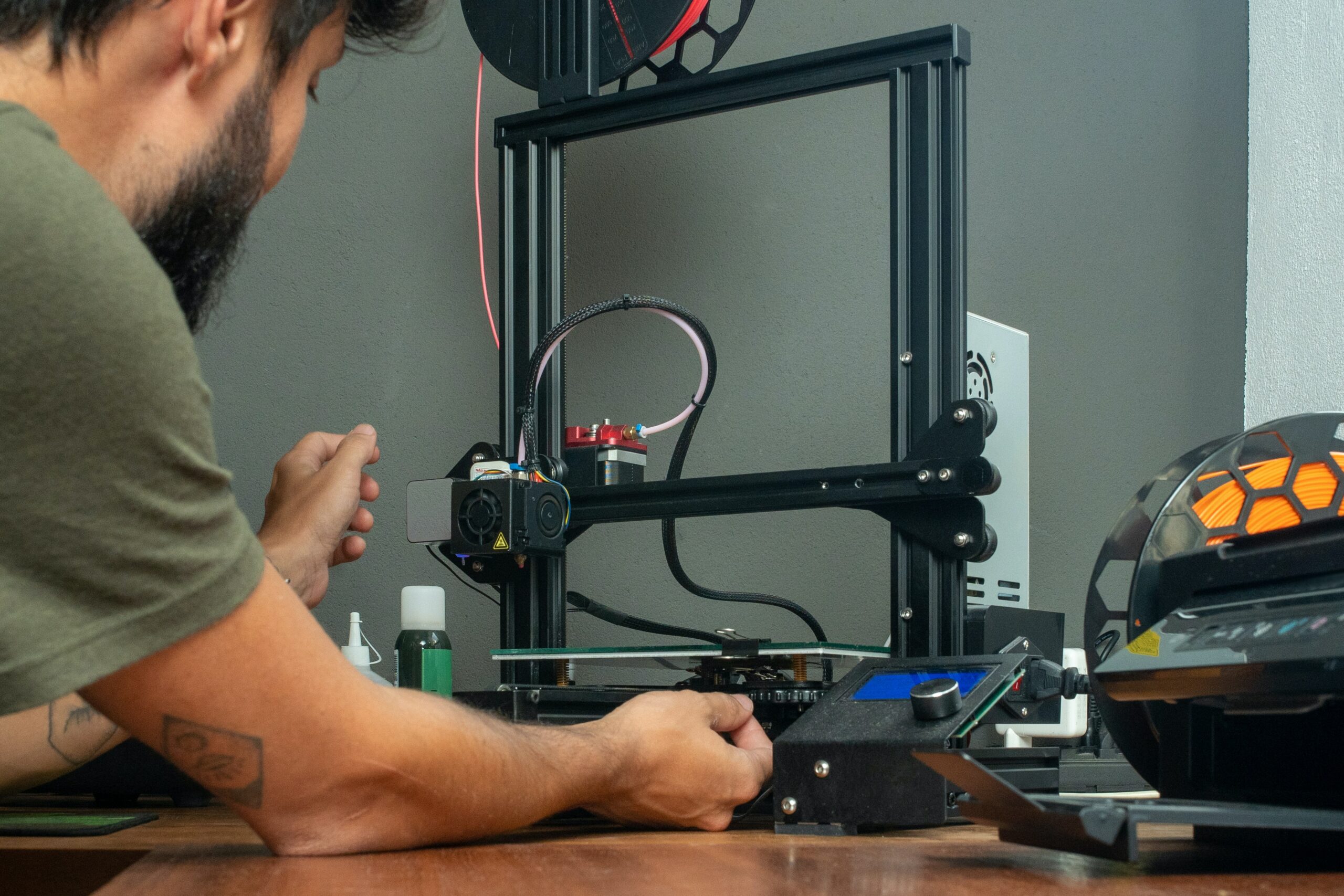

Additive Manufacturing, aka Digital to Physical

“3D printing or additive manufacturing is constructing a three-dimensional object from a CAD or digital 3D model.

The material can be assembled using several computer-controlled processes, frequently layer by layer. Deposition, joining, or solidification are all carried out after that.

3D printing has disrupted traditional manufacturing for several years, and industrial giants are using 3D printing to build prototypes and even final production models. The future of 3D printing could change many industries, from healthcare prosthetic creation to weapons manufacturing to homebuilding.

Unsplash+In collaboration with Getty Images

Human-Machine Interfaces

An HMI is “the hardware or software through which an operator interacts with a controller. An HMI can range from a physical control panel with buttons and indicator lights to an industrial PC with a colour graphics display running dedicated HMI software.”

Although we’ve had proto-HMIs since the advent of the computer, a new generation of hardware and software tools is emerging, allowing operators to better monitor and control industrial processes with better safety and operational efficiency.

The most everyday example of an HMI is a touchscreen – yes, we all have an HMI in our hands, and the same tech that powers our phones will eventually become ubiquitous within manufacturing.

Augmented Reality

“Augmented reality is an interactive experience that combines the real world and computer-generated content. The content can span multiple sensory modalities, including visual, auditory, haptic, somatosensory and olfactory”.

The clearest example of AR within manufacturing is using augmented reality to inspect virtual designs before committing to fabrication.

This semi-virtual, digital overlay fabrication and manufacturing testing system has precise, beneficial applications. Still, we’re only in the birthing stages of what AR can do within the manufacturing and industrial sectors.

Industrial Internet of Things

“The Internet of Things (IoT) refers to a network of physical devices, vehicles, appliances and other physical objects embedded with sensors, software and network connectivity that allows them to collect and share data”.

Unsplash+In collaboration with Getty Images

The IoT is already a reality in our homes and is rapidly spreading across manufacturing floors. Industrial devices (connected via an industrial internet) that can communicate digitally with each other significantly reduce downtime and vastly improve efficiencies and are increasingly present across Cloud and edging computing within industrial contexts as well as within energy management, robotics and cognitive computing.

The Cloud

“The Cloud” refers to servers accessed over the Internet and the software and databases run on those servers. Cloud servers are in data centres worldwide”.

The Cloud is another technology from the service sector into manufacturing. It offers manufacturers the same scalability benefits, redundancy and cost advantages as it does to the service sector but differs fundamentally.

Cloud manufacturing has unique benefits, such as data accessibility across multiple sites and devices, capability sharing, increased sustainability, flexibility and end-to-end due diligence from customer order to delivery.

Cyber Security

“Cyber security’s core function is to protect the devices we use (smartphones, laptops, tablets and computers) and the services we access – both online and at work – from theft or damage. It’s also about preventing unauthorised access to the vast amounts of personal information we store on these devices and online”.

New risks come with all this new connectivity, device-based work, and extensive data access. Robust cyber security is critical to protecting vital data and instruments, people and workplaces. When the scale of the problem exponentially grows YoY, manufacturers must be aware of the threats and able to mitigate the worst.

As “smart” manufacturing increases, those systems are more vulnerable to risk. There are more significant risks when “legacy equipment, fragmented security infrastructure, large workforces with varying levels of information technology training” come into play — the foundations for a new normal of chronic cybersecurity threats for Industry 4.0 are here.

The Bottom Line

Whilst this is not a comprehensive list of Industry 4.0 technologies, it’s a tiny yet focused sampling of how manufacturing in 2023 and beyond will look.

Photo by Ales Nesetril, on Unsplash.

Photo by Ales Nesetril, on Unsplash.

And, just like the first industrial revolution drastically increased productivity, so will this digital one bring new productive efficiencies to light. The key to success here, for both companies and employees, is to embrace these new, novel technologies, master them, and become an industry leader within them.

Submit Your CV or Search for Jobs to learn about the available roles we have in industry and other sectors.

Send Us Your Vacancy and one of our consultants will be in contact to discuss your requirements and how we may assist.

No comments:

Post a Comment