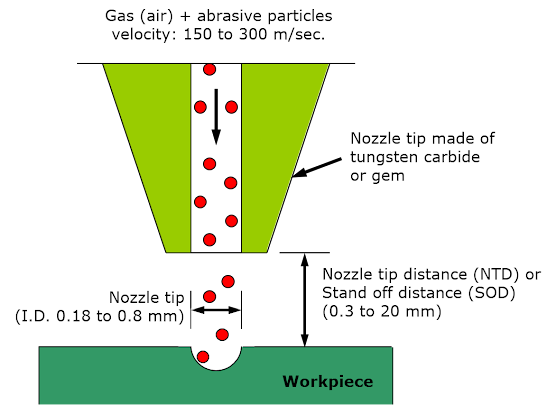

In abrasive jet machining process, a focused steam of abrasive particles (of size 10 to 40 microns) carried by high pressure gas or air at a velocity of about 150 to 300 m/sec is made to impinge on the work surface through a nozzle, and the work material is removed by erosion by the high velocity abrasive particles. The inside diameter (ID) of the nozzle through which abrasive particles flow is about 0.18 to 0.80 mm and the stand-off distance (i.e. distance between nozzle tip and workpiece) is kept about 0.3 to 20.0 mm. The process can be easily controlled to vary the metal removal rate which depends on flow rate and size of abrasive particles. This process is best suited for machining super alloys and refractory type of materials, and also machining thin sections of hard materials and making intricate hard holes. The cutting action is cool because the carrier gas serves as coolant.

|

Abrasive Jet Machining (AJM) Principles |

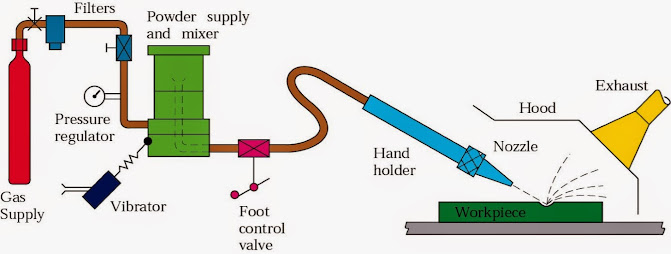

The basic Units of AJM

|

| AJM setup |

Abrasive Jet Machining (AJM) Advantages:

- This process is quite suitable for machining brittle, heat resistant and fragile materials like, glass, ceramic, germanium, mica etc.

- It can be utilized for cutting, drilling, polishing, deburring, cleaning etc. of the materials.

- The depth of damage to the surface is very little.

- Holes of intricate shapes could be produced efficiently.

- The surface machined can have good finish (by controlling the grain size mainly).

AJM Disadvantages:

- The tapering of hole especially, when the depth of the hole is more, becomes almost inevitable.

- A dust collecting chamber is a basic requirement to prevent atmospheric pollution to cause health hazards.

- The abrasive particles may remain embedded in the work surface.

- Abrasive particles cannot be reused.

AJM Applications:

- Abrasive jet machining is best suited for machining brittle and heat sensitive materials like glass, quartz, sapphire, ceramics etc,

- It is used for drilling holes, cutting slots, cleaning hard surfaces, deburring, polishing etc.

No comments:

Post a Comment